Stabilizers have long been the great unsolved problem in the world of keyboards. Their function is straightforward; they prevent longer keys (such as the spacebar) from seesawing upward at one end when the opposite end is pressed down. Current solutions serve that purpose well enough, but the issue is: they all sound awful. Taeha Kim's face in response to the rattle of an unmodified traditional stabilizer—in a video it amuses me to note has been viewed millions of times—sums up how all of us keyboard nerds feel.

For decades this has been the core absurdity of luxury typing: you can buy a $4,000 hyper-engineered super-premium board with exotic materials, rare hybrid switches, hidden fasteners, leaf springs, and custom gaskets interfacing every surface. Yet among its most critical components can be found a fundamentally flawed mechanism that has seen little refinement since its inception.

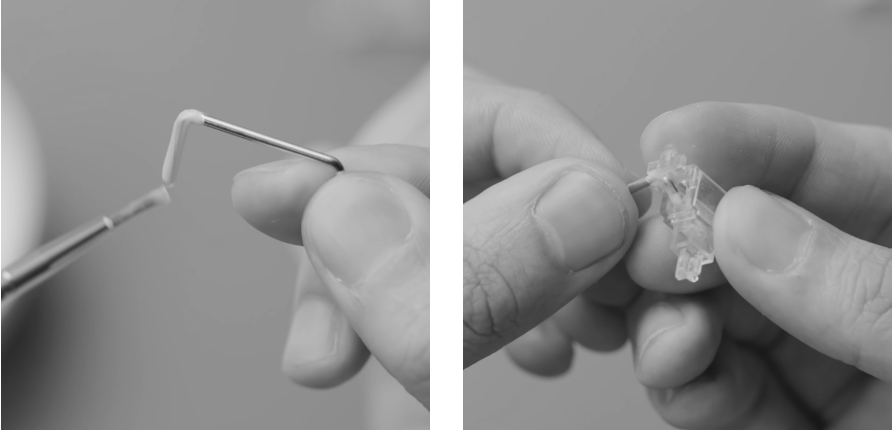

Hobbyist modders thus spend long hours hand-lubricating and tuning their stabilizers to eliminate rattle, painstakingly brushing high-viscosity grease into the interstices between parts.

This chore requires a delicate dance between desirable dampening and unwanted key sluggishness. It works, but it's an ugly hack—an acoustic band-aid that is tricky to perform consistently and whose efficacy erodes over time as the grease seeps away.

Because it is fiddly and annoying, it is easy to mistake lubing for a fancy atelier process that is part of the very definition of a high-end keyboard. But I've always suspected that it's really just a ham-fisted way to compensate for bad engineering—effectively, a concession of defeat. After five years inquiring deeply into this question, including multiple patents issued and pending and project expenses running well into the six figures, I can now with some confidence confirm those early suspicions.

Especially since the band-aid solution is more or less serviceable, though, one might reasonably ask about why anyone should care so much. The answer in my case is that I have for some years been on a mission to create what is, to my sensibilities, the perfect luxury keyboard—one that anyone, whether a hardcore hobbyist or keyboard neophyte, can buy, plug in, and immediately and indefinitely enjoy. That keyboard, called the Seneca, is meant to be my expression of the best typing experience obtainable, and every component of it is fully custom to my original designs. It's about some very sentimental artistic and emotional goals, and so it's emphatically not about engineering perfection or technical accomplishments for their own sake. But, for a project in which I've invested so much of myself, I simply felt that poorly engineered stabilizers could have no home.

For this reason, I’ve always known that noisy stabilizers were a problem that Norbauer & Co. would somehow eventually have to invent its way out of, having to find an approach better than anything that yet existed. I had done something similar before with the Heavy Grail, heedlessly setting off to conquer a technical mountain that would prove a far steeper climb than I would have imagined, but ultimately successfully doing what I set out to. What I didn't realize at the outset this new journey, of course, was that I would—in some dubious mixture of folly and obsessive perfectionism—end up uncontrollably traversing its difficult terrain three times over.

As you'll see, I brought no particular engineering brilliance to this problem and thus can claim no glory from any success that may have resulted. What got me to the ultimate solution was little more than recklessly training a personal cash bazooka on the question, and being doggedly, irrationally—truly insanely—persistent in my conviction that there must be a perfect answer.

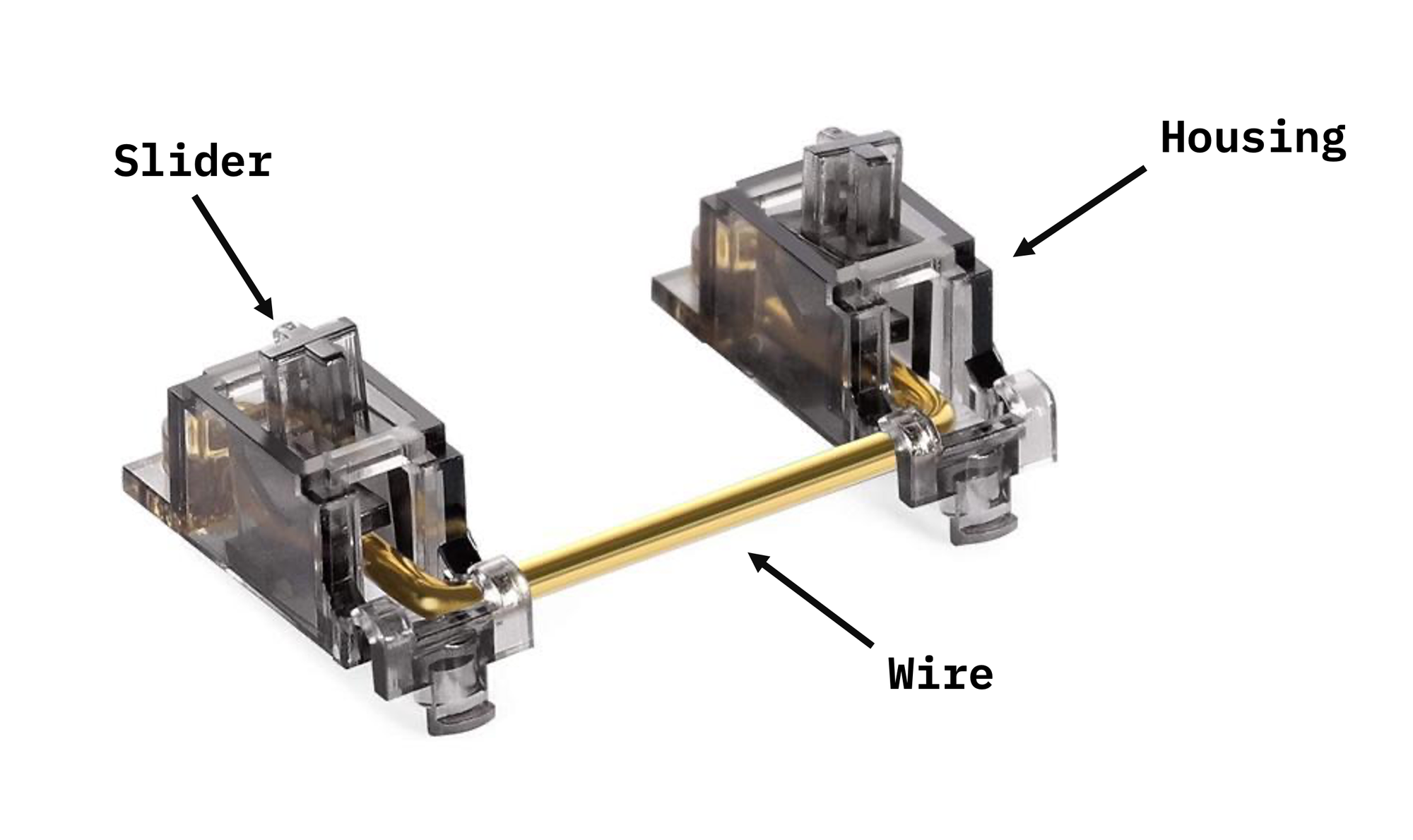

Below is the architecture of a traditional Cherry-type stabilizer. A keycap is connected to two sliders via a press fit onto their cruciform mounting points. Those sliders move up and down with the key travel, and a spring-loaded switch (also pressed into the keycap) is situated between the two stabilizing ends. A rotating wire clipped into the stabilizer housings has two extension arms that insert into the two sliders, pulling them up and down together in tandem and thus creating the anti-seesaw effect.

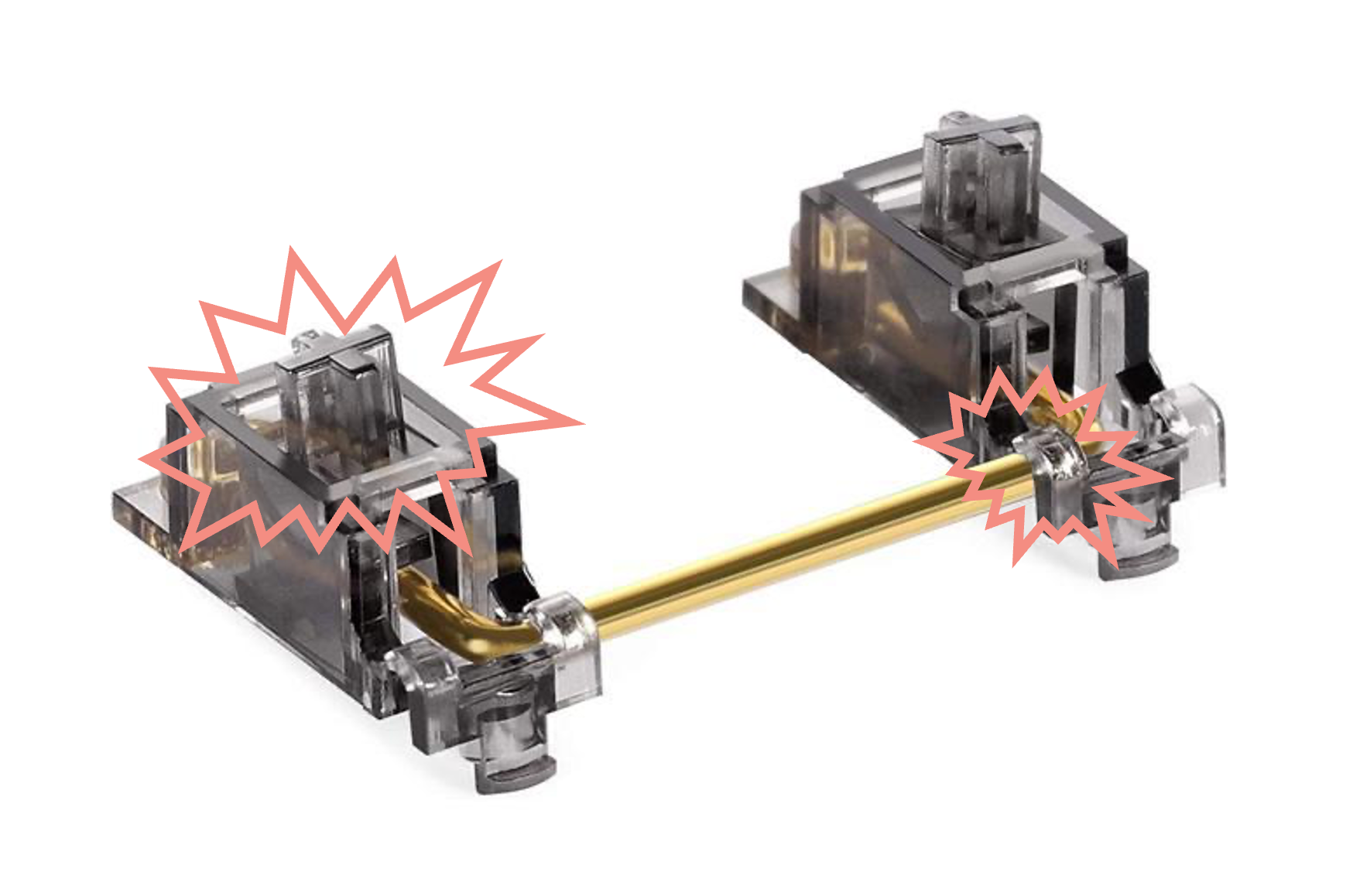

There are two primary sources of unwanted sounds. I'll formalize some keyboard community terminology here by calling the first rattle, which refers to the sound of the hard wire linkage striking against the hard plastic surfaces in the interior of the slider. This is by far the most prominent and displeasing source of stabilizer noise.

Rattle: wire bangs against slider

The second more subtle source of unwanted sound can be termed ticking, and it refers to the sound of either the slider or wire moving against the housing.

Ticking: slider or wire bang against features in the housing

There is one additional complicating factor, which is that long keys like spacebars frequently vary between manufacturers in their stem spacing length. Any widely applicable stabilizer design must therefore accommodate a remarkable degree of dimensional variability.